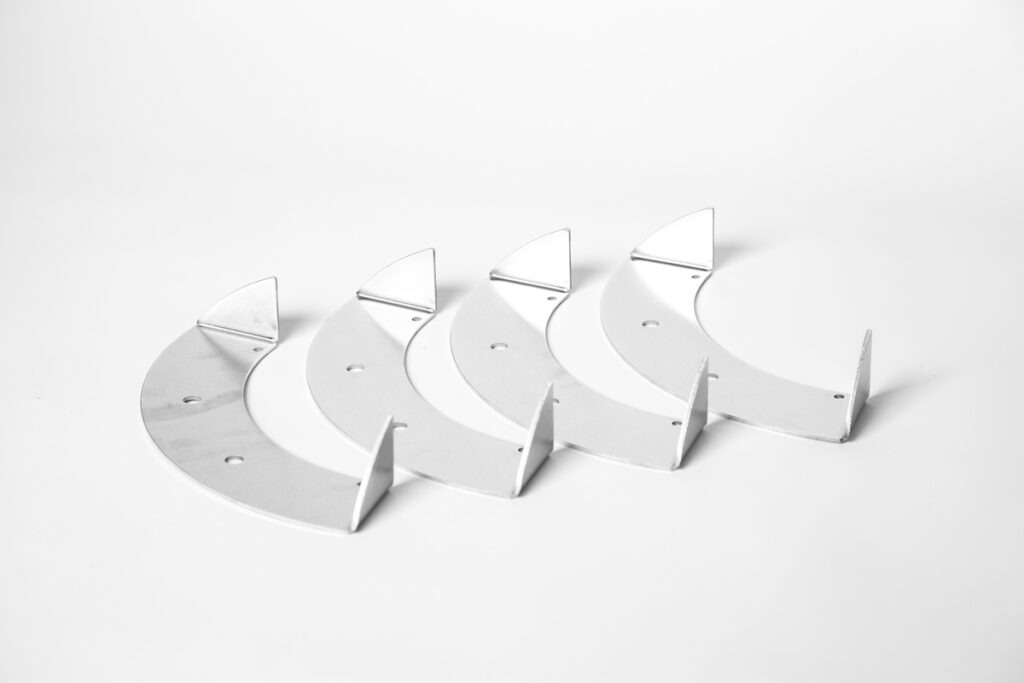

Precision Metal Cutting Services for OEMs

Laserfab specializes in precision, high-speed, custom, metal laser cutting services for a wide variety of applications and industries. With advanced equipment, streamlined processes and an expert team, we have everything needed to deliver exceptional quality parts as efficiently and cost-effectively as possible.

Our continued investment in the latest CNC laser cutting technology combined with our commitment to ongoing training and education, means that we know how to produce high-quality parts that meet even the most exacting standards. Best of all, every part that leaves our shop has been fully processed, inspected, and is ready for you to utilize upon delivery.

Materials

- Mild Steel

- Stainless Steel

- Aluminum

- Copper, Brass, Bronze

Cutting Specs

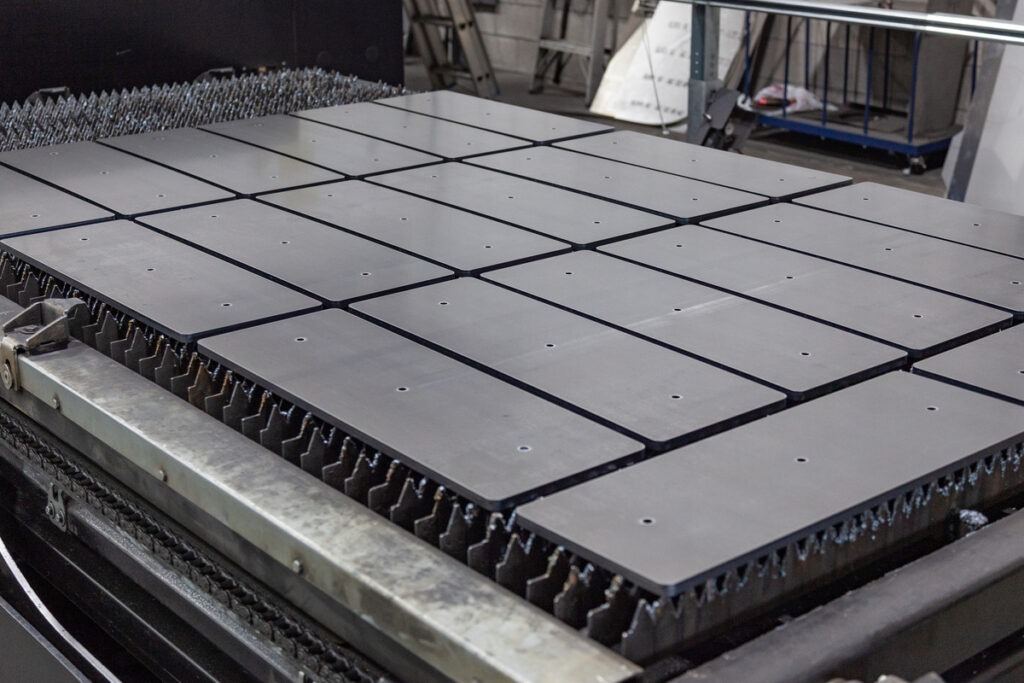

- Up to 80″ x 160″

- Starting at 26 ga.

- Up to 1″ Thick

Machine Specs

- 5 Fiber Lasers

- 2D Cutting

- Up to 20kW Cutting Power

Why Choose Laserfab for Laser Cutting?

Cutting-Edge Equipment

Laserfab accomplishes our laser cutting processes using cutting-edge fiber laser technology that facilitates increased laser cutting speed and superior material processing capabilities. Under the control of our experienced operators, this high-tech equipment can produce perfect parts for all of your metal production needs.

Advanced Software

Our lasers run on state-of-the-art software such as AutoCAD, SOLIDWORKS, and Lantek Expert to ensure accuracy and efficiency. Achieving the highest levels of precision and dependability on our end means less stress and delay on your end, and a supply chain partner that you can count on to deliver the parts you need correctly.

Seasoned Professionals

At Laserfab, precision metal fabrication is our passion, and we take our jobs very seriously. All of our employees have worked in the steel, aluminum, stainless steel, sheet metal and fabrication industries for many years. This experience shows in the quality of the products and services we provide to our customers day in and day out.

Request a Laser Cutting Quote

If you’re interested in learning more about Laserfab’s metal cutting, metal forming, and value added services, call us at 866-297-6149 or scroll below and fill out the simple online form. We look forward to hearing from you!